Our experienced technical group can provide cost effective solutions to many problems.

Noel Technologies Advanced Lithography Services include engineering support for reticle layout, process development, insuring success of each design.

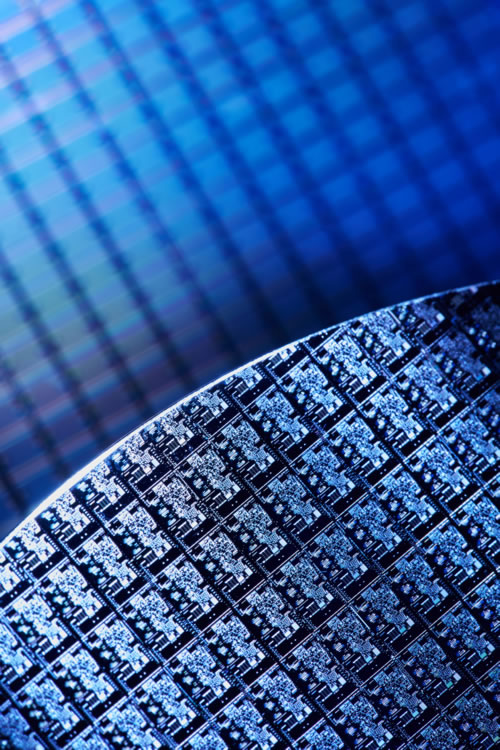

ASML 5500-300: DUV (248nm)

150mm Substrate, Semi-Std Flat, 675um +/-25um Thick Silicon or Glass

Minimum Resolution >250nm

Field Size= 20mm X 20mm

CAD & Layout Support for Required Reticles.

DUV resist spin coatings

- BARC

- TARC

- Thickness contour maps available

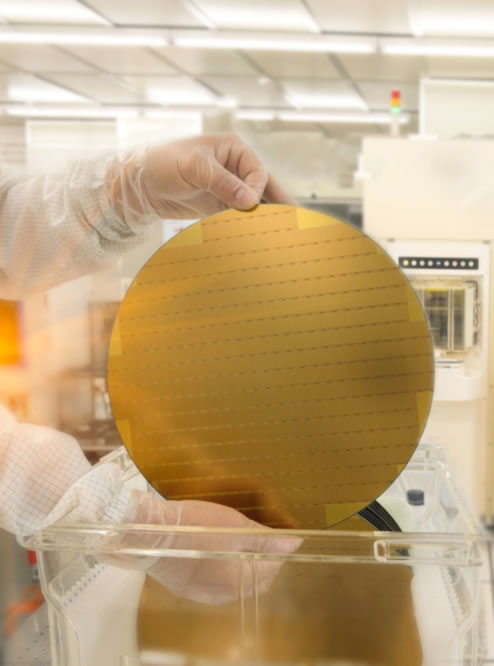

Outsource your ASML “Zero” layer to Noel Technologies

- Start material with patterned and etched “zero” layers

- Etch depth SPC controlled to 1200A ±200A

- Pre-alignment & fine alignment characterization of all wafers, with batch statistics, available

Noel Technologies as your lithography cell backup and short term capacity add partner

- Lithography cell qualified to customer specifications

- Matched to customer WIP

- Regular lithography cell monitoring provides risk free switching

Calibrated wafer grid definition and target placement optimization

- Patterned, etched, alignment targets (for any system) placement to an accuracy of <15nm

- Alignment targets (for any system) on both sides of the wafer, with an overlay accuracy of <300nm (front to back)

Lens distortion and Focal Plane metrology

- Characterize and monitor your lens X,Y distortion

- Characterize and monitor your lens Focal Plane

Pilot production runs: Lab to Fab

- Build your product using a foundry lithography system, it’s scalable, ready for production

- Outsource your critical layers to reduce your costs

Research and Development

- Explore your next technology node using Noel’s lithography cell

- Develop your first prototype devices