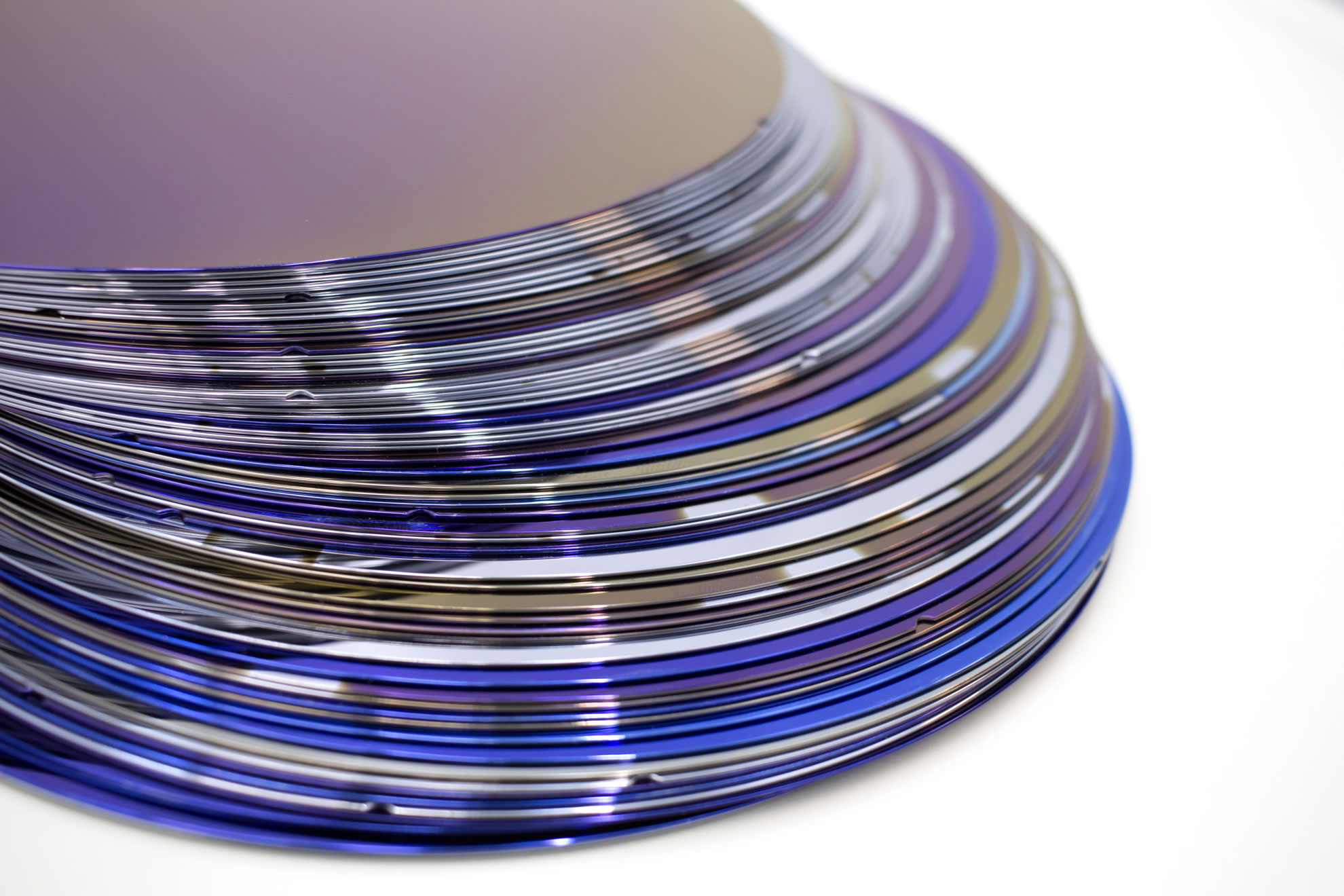

Reclaimed Wafers

Noel Technologies, Inc. offers full wafer recovery:

- extending the life of wafers and

- offering a cost effective solution to customers.

Reclaimed wafers may be made from prime wafers that have been stripped of

- photo resist

- oxide

- poly

- nitride

- metals

They are mechanically repolished to remove film, surface scratches and residual patterns.

After polishing, wafers are cleaned and batch-sorted for thickness, bow/warp/flatness and resistivity. Thin films may then be applied to complete the process. The number of times a wafer may be reclaimed is limited, as the process physically reduces the thickness of the substrate. Eventually, test wafers become damaged, too deeply scratched or too thin to be reclaimed.

Recycled Test Wafers

The wafer recycling process involves a non-mechanical, wet chemical etch that will remove many thin films. No substrate material is removed and surface flatness characteristics are not changed.

Unlike wafer reclamation, this process is ineffective for removing scratches or haze. Wafers may be recycled with the proviso that they meet particular incoming specifications. Generally, for successful recycling, wafers must be free of scratches greater than a total of 3cm in length. Haze, ghost patterns and pitting must be minimal. Wafers with cracks, chips or warping cannot be recycled successfully.

Process Repeatability

One of the major benefits of wafer recycling is the repeatability of the process. Wafers processed by Noel may be routinely recycled ten times or more. If recycled wafers become scratched or slightly damaged, they are flagged and may then be reclaimed. The cost-saving implications as well as the environmental benefits of this strategy is beneficial to our customers.

Incoming Inspection

Upon receipt of material, Noel visually inspects wafers for chips and cracks. Wafers with these types of defects will be rejected and returned unprocessed. Noel does not offer particle specs, or surface guarantees on recycled material. Noel is not responsible for wafers broken in process.

| DEFECTS | REJECT | ACCEPT |

| Finger Prints | 0% | 100% |

| Chips/Cracks | 100% | 0% |

| Water Spots/Slurry | 0% | 100% |

| Haze | Customer Spec | Customer Spec |

| Scratches | Customer Spec | Customer Spec |

Modifications to Noel’s Standard Specifications must be submitted in writing, prior to acceptance of order. Proprietary information – not to be disclosed to any third party. |

||